Research Project to Boost Hydrogen Vehicle Safety

A new sensor-based structural monitoring system is being developed as part of a research project at Fraunhofer Institute for Structural Durability and System Reliability (LBF) in Germany. How could this help to improve the safety of hydrogen vehicles?

The system will enable continuous surveillance of hydrogen pressure tanks and it is designed to reveal internal damage that visual inspections cannot detect.

Currently, the latest fuel cell vehicles carry hydrogen in pressurised tanks, up to 700 bar. Regular maintenance is mandatory. However, a tank inspection which is required every two years, just consists of an external visual inspection.

A structural health monitoring system is being developed to tackle tank damage

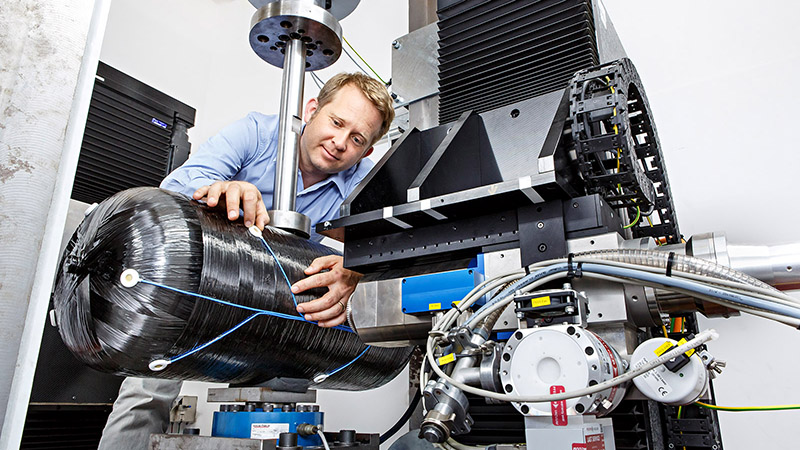

The tanks are made from fibre-reinforced composites (FRC). Compared to metal tanks, these are ideal for use in the mobility and transport sector due to their low mass.

For safety reasons, the hydrogen pressure tanks are subjected to extensive testing before they are used for the first time to ensure safe operation throughout their service life.

The visual inspections that are specified to check for external damage to the tank currently cannot do this.

As an alternative, damage can be detected by continuously monitoring the pressure vessel. This is known as structural health monitoring (SHM).

This is why the research that LBF is undertaking is essential. The researchers are developing a structural health monitoring (SHM) system to tackle the issue.

No hydrogen tasks will be wasted

The work by LBF is focused on acoustic emission sensors. If a single carbon fibre tears in the pressure tank, a sound wave is generated and travels through the fibres.

Sensors can then detect this high-frequency sound wave, allowing them to determine the number of broken fibres.

Johannes Käsgen, a Scientist at Fraunhofer LBF, explained that the research project will help make decisions: “To give an example, our technology provides inspectors from the German technical inspection associations (TÜV) with objective information about the stresses on the tank after an accident, enabling them to decide objectively whether it can be reused or needs to be replaced.”

Another function is to help reduce maintenance costs and make sure that the tanks are used safely throughout their entire service life.

Continuous on-board structural monitoring assures an increased level of safety for hydrogen vehicles because potential damage can be assessed even in the case of minor impacts. It means that the unnecessary replacement of hydrogen tanks can be avoided.

Research into the number of sensors needed for structural monitoring is underway

Fibre-optic strain sensors are also being looked at and integrated into the tanks, helping to enable the continuous automated monitoring of strains.

Unlike conventional strain sensors, the fibres are suitable for monitoring carbon fibre-reinforced plastics due to their resilience to high material strains and load cycles.

The research teams are currently investigating how many sensors are required for structural monitoring, which adhesives are the most suitable for attaching them to the hydrogen tank, and where they need to be positioned.

A test vehicle will be fitted with sensors and onboard structural monitoring before validation with a virtual crash and a real-life test setup. In the future, the partners aim to develop the complete system into a standard status monitoring system.